How to Properly Clean and Torque CNC Tool Holders

Let’s discuss the importance of properly cleaning and torquing your CNC tool holders. In the world of computer numerical control (CNC) machining, maintaining the integrity of your equipment is crucial to achieving precision, efficiency, and the desired output.

One critical aspect of this maintenance is ensuring that your CNC tool holders are cleaned and torqued properly. Let's dive into the reasons why this is so important, and how you can maintain your CNC tool holders for optimum performance.

WAYS TO SUPPORT US

Why Proper Cleaning and Torquing Matters:

1) Accuracy and Precision

-

Minimize runout

-

Improve tool life

-

Ensure finished parts meet specifications

2) Tool Life

-

Prevent premature wear on tools and holders

-

Reduce downtime for replacements

Safety

-

Minimize risks of cutting tools coming loose

-

Keep workplace safe and equipment in good working order

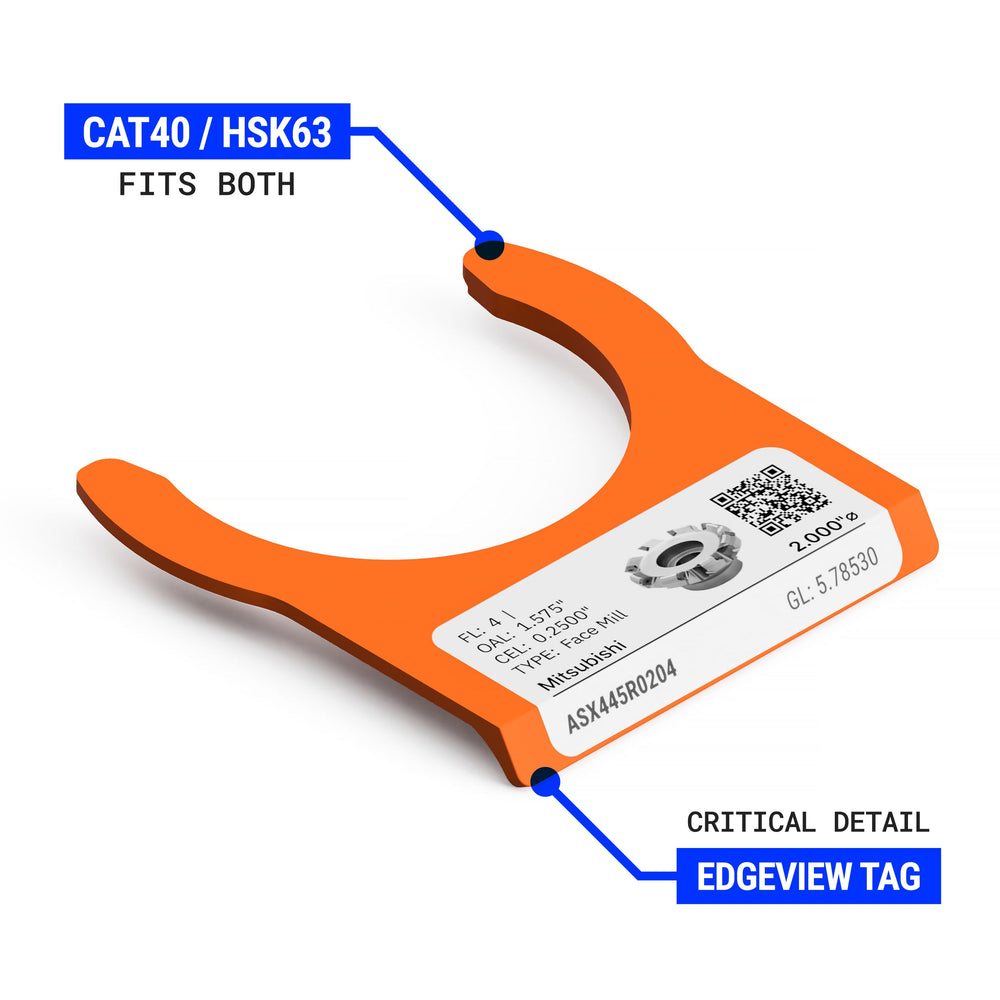

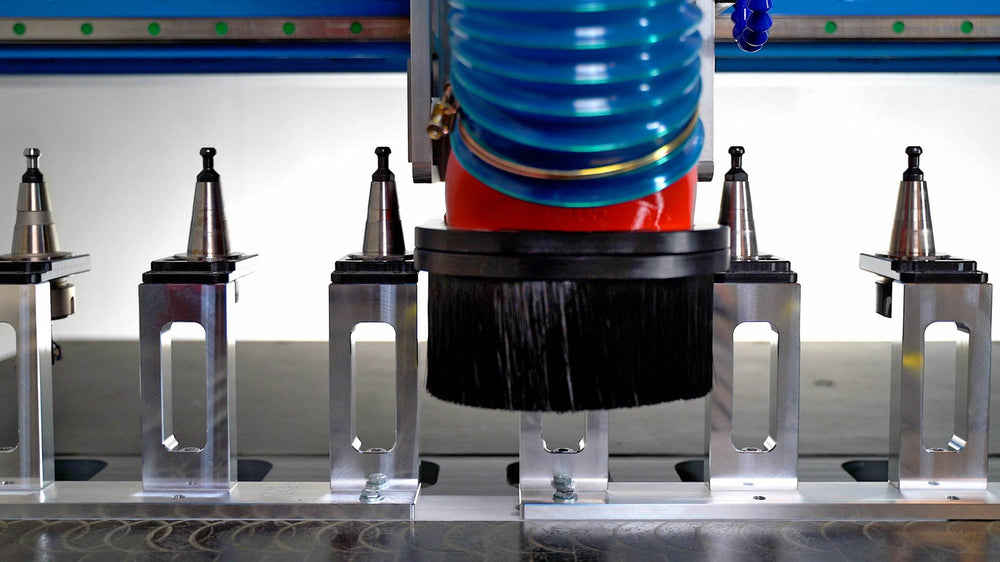

How to Clean and Torque Your CNC Tool Holders:

-

Cleaning

-

Remove dirt and debris with a lint-free cloth or soft brush

-

Use a specialized cleaning solution for stubborn contaminants

-

Avoid using compressed air

Supplies and Tools:

-

Lint-free cloth or soft brush

-

Specialized cleaning solution

-

Safety glasses and gloves

-

-

Inspection

-

Check for signs of wear or damage, such as cracks, corrosion, or galling

-

Replace damaged tool holders as needed

Supplies and Tools:

-

Bright light source

-

Magnifying glass (optional)

-

-

Lubrication

-

Apply a thin layer of rust-preventative oil or grease to taper, flange, and clamping surfaces

-

Protect tool holder from corrosion and ensure smooth operation

Supplies and Tools:

-

Rust-preventative oil or grease

-

Lint-free cloth or applicator

-

-

Torquing

-

Use a torque wrench to apply the correct amount of torque as specified by the manufacturer

-

Avoid over-tightening or under-tightening to prevent tool holder deformation or tool slippage

Supplies and Tools:

-

Torque wrench (calibrated)

-

Manufacturer's torque specifications

-

Conclusion

Properly cleaning and torquing your CNC tool holders is vital for maintaining precision, extending tool life, and ensuring the safety of your workplace. By following these steps and adhering to the manufacturer's guidelines, you can keep your CNC equipment in optimal condition and enjoy the benefits of efficient, accurate machining.

DO US A FAVOR — SUBSCRIBE TO OUR YOUTUBE?

Click to subscribe ⤴

Leave a comment