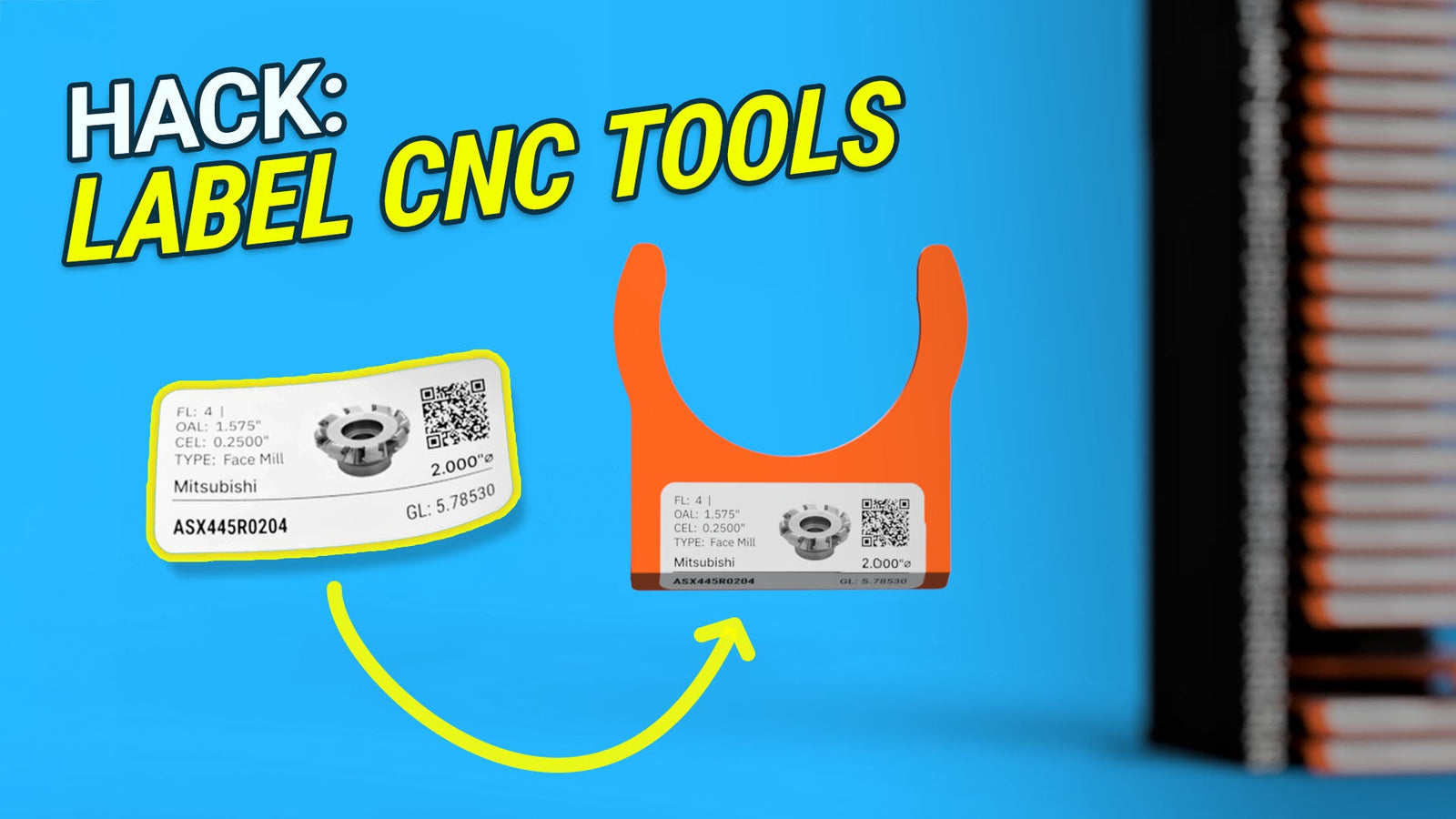

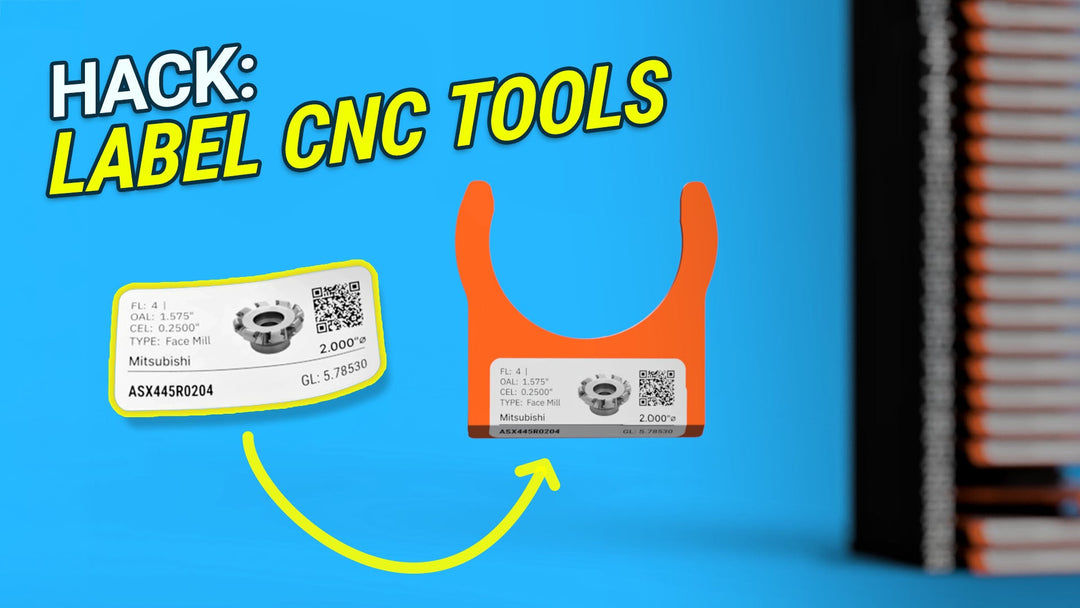

Create labels and organize your CNC tools with tags

After many years we have a CNC tool labeling and organization system we actually like to use. You may have landed here because you've been struggling to create your own.

If you keep track of your tools in a spreadsheet, Airtable, ERP, or just the Fusion tool library that will all work for how we generate tool labels.

You can do one at a time or follow along in the video to data merge a CSV file of a batch of tools and turn them into tool tags.

See how we create and use CNC Tool Tags

Why "Tag" your CNC Tools

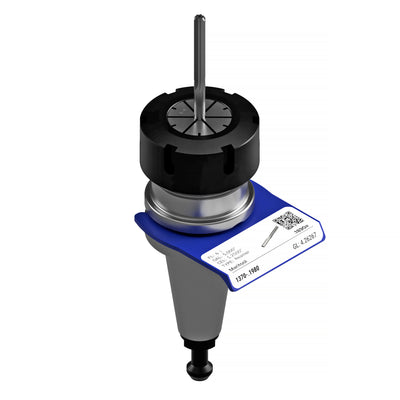

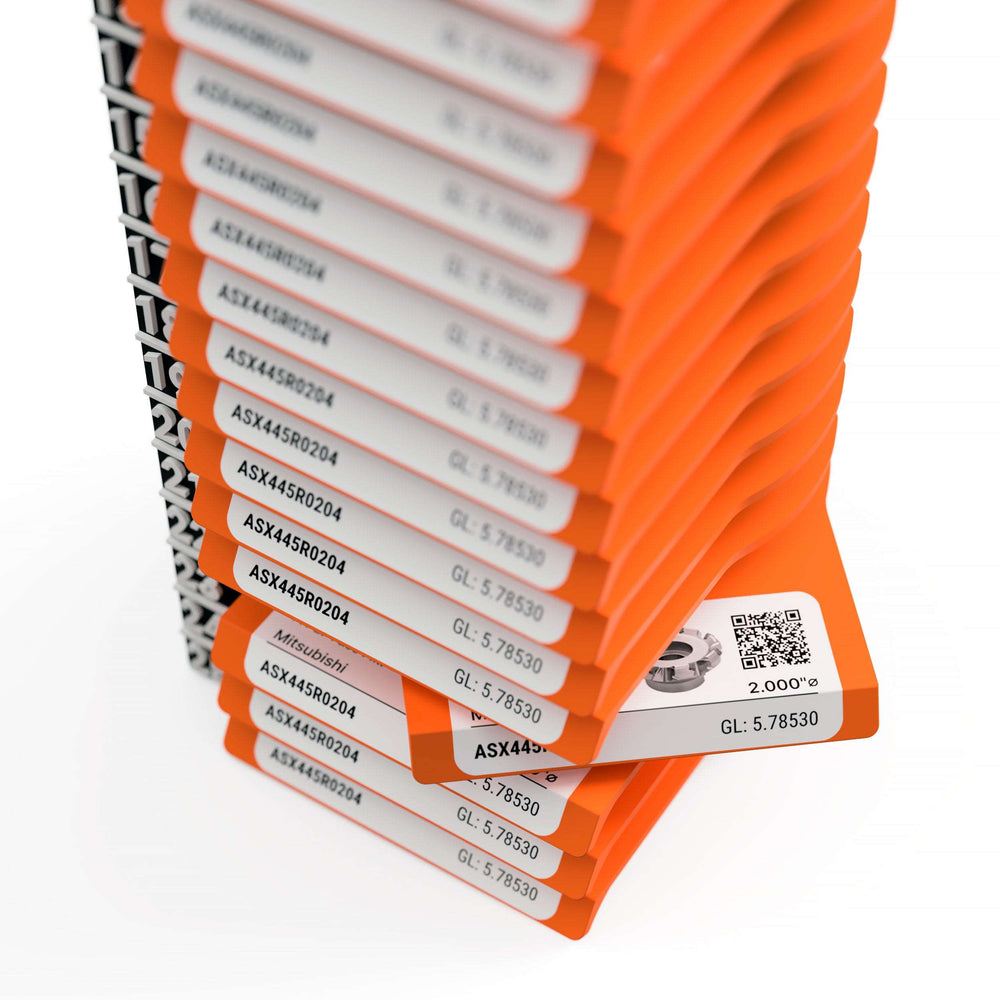

- Gauge Length & Tool Type: Tool tags provide a reliable way to keep critical tool details like gauge length and tool type visible, so you’re not relying on memory or guesswork. This visibility is crucial for precision setups, ensuring you don’t waste time recalibrating or accidentally using the wrong tool.

- Instant Identification: Once a tool is installed in its holder, identifying it by sight alone can be challenging—even for experienced operators. Tool tags let you instantly know exactly what each tool is, minimizing the risk of mistakes and keeping your workflow on point.

- Efficiency in the Shop: In a busy shop, quick and clear tool identification is everything. Tool tags keep your tools organized and reduce downtime, so operators can focus on running jobs efficiently instead of double-checking tool specs or setups.

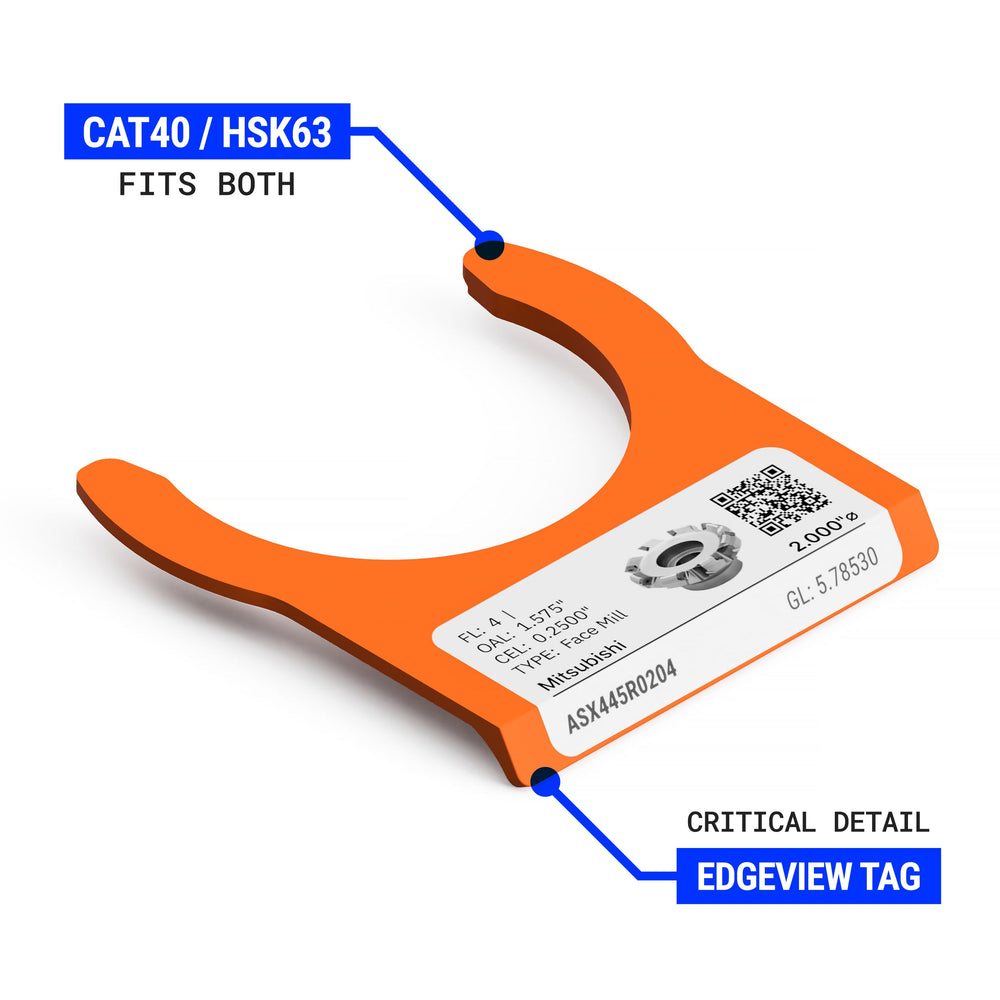

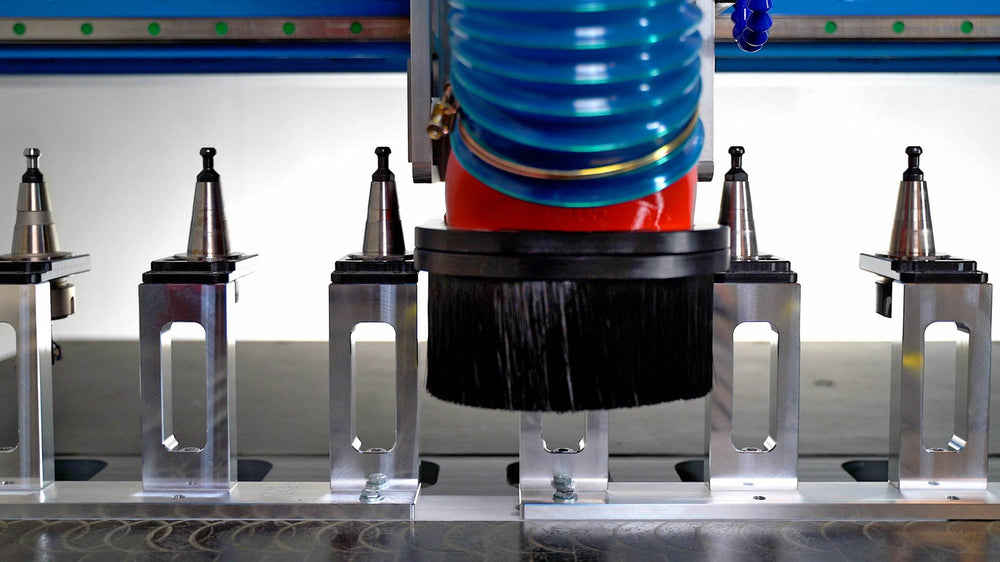

Portland CNC Edgeview Tool Tags

View all Tool Tags & Towers

Label Design

Watch the video above to see how we designed our tool tag labels.

Key Links

Includes affiliate links

- Dymo 450 Labelwriter – 550

- Thermal Labels – 1 x 2.125" – For all but TTS

- Thermal Labels – 1 x 1.5" – For TTS

- Dymo Connect – Download

- Bonus – Barcode / QR Code Scanner

Downloads

- Tool Tag Sample CSV – fill in your tools in our example spreadsheet

- Tool Tag Template Dymo – file to customize and data merge in Dymo Connect

- Download our PDX CNC tooling list as a CSV

Hi Faadin, yep we ship to Canada and the HSK63A tags come in orange as shown.

I wanted to buy some of the tag holders for the hsk63, do you ship to canada? and are there different colors to choose from or just orange?

Leave a comment