Maintenance and Repair Guide of ShopSabre F4 Vacuums

If you’ve had a ShopSabre F1 or F4 hold-down vacuum for longer than a year you most likely need to do maintenance or part replacement by now. This system is great because the motors can be used in a single-phase-only environment - which is how we started in Justin’s home garage.

We’ve compiled what you need to know to replace the brushes as well as the parts to do so.

👋 HEY!

Links below contain affiliate tags which earn us a small reward when you purchase. We appreciate this gesture of thanks for the effort we’ve put into making this information available.

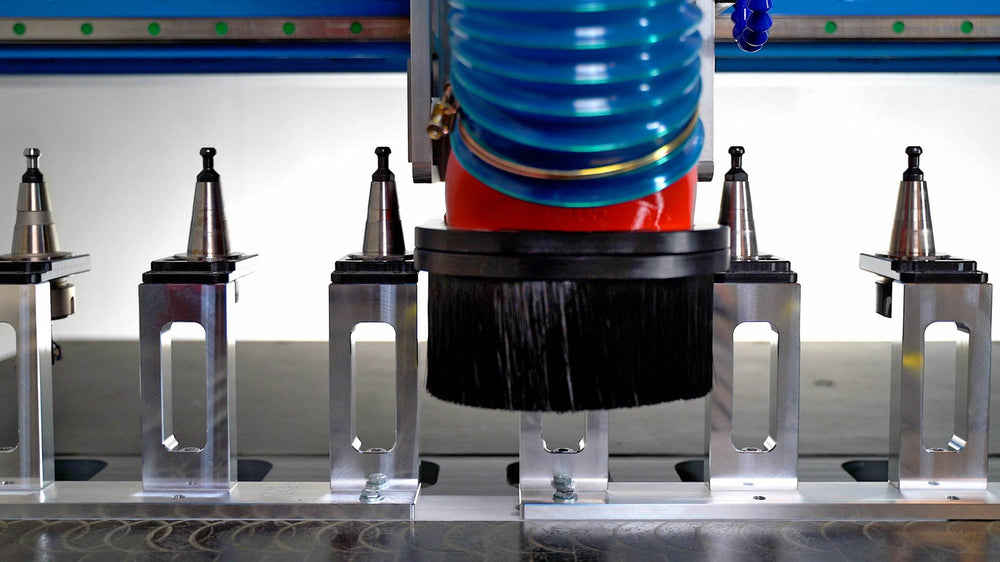

Brush Check & REPLACEMENT

Each motor, there are four in the F4, needs the brushes checked every 750 hours and likely replaced before 1500 hours of use. Our experience is brushes last less than 1500 hours so the halfway check is smart.

See our F4 Brush Maintenance Guide

PARTS

Replacement F4 Brushes

We keep at least 4 of these on hand at all times. We keep a regular schedule to check the motors but they also seem to just lose a big chunk of the brush and surprise you every so often.

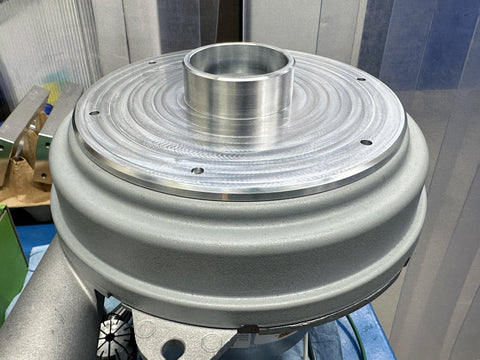

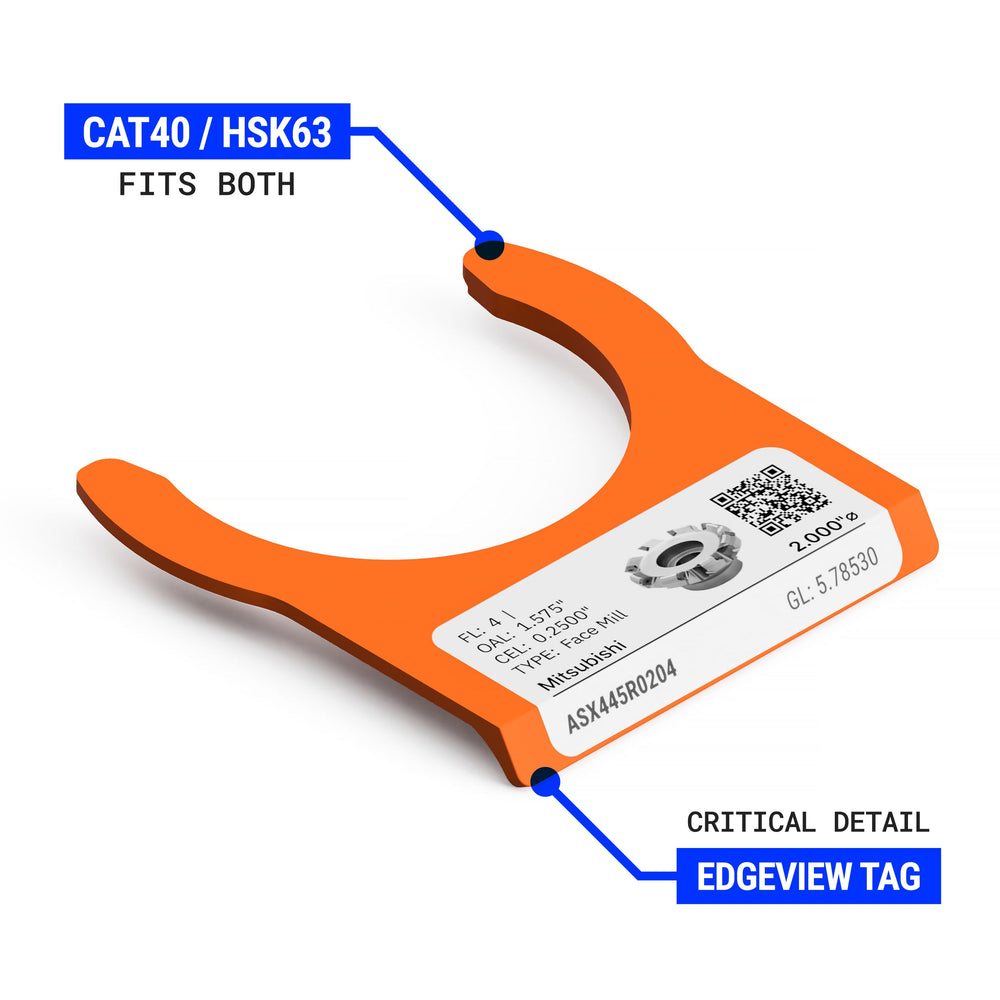

Replacement F4 Motors

At some point replacing the brushes won’t do it. Sort of like when your Subaru timing belt isn’t serviced soon enough, we’ve found that the motor can be toast if the brushes aren’t replaced in time. That or they simply just wear out.

When you need to get a new one this is what you need to get.

You will also need to replace the custom flange on the intake side of the motor.

We sell a ready-to-use F1/F4 motor 👇

Motor Intake Flange

You’ll need to replace the intake port that’s riveted to the motor housing.

We now offer that part a low markup made in-house. Save about 40% and DIY your own motor replacement with our flange.

Hour Meters

We added these Hour Meters to each of our F4 motors to better track usage for maintenance.

Have you seen our ShopSabre Upgrades?

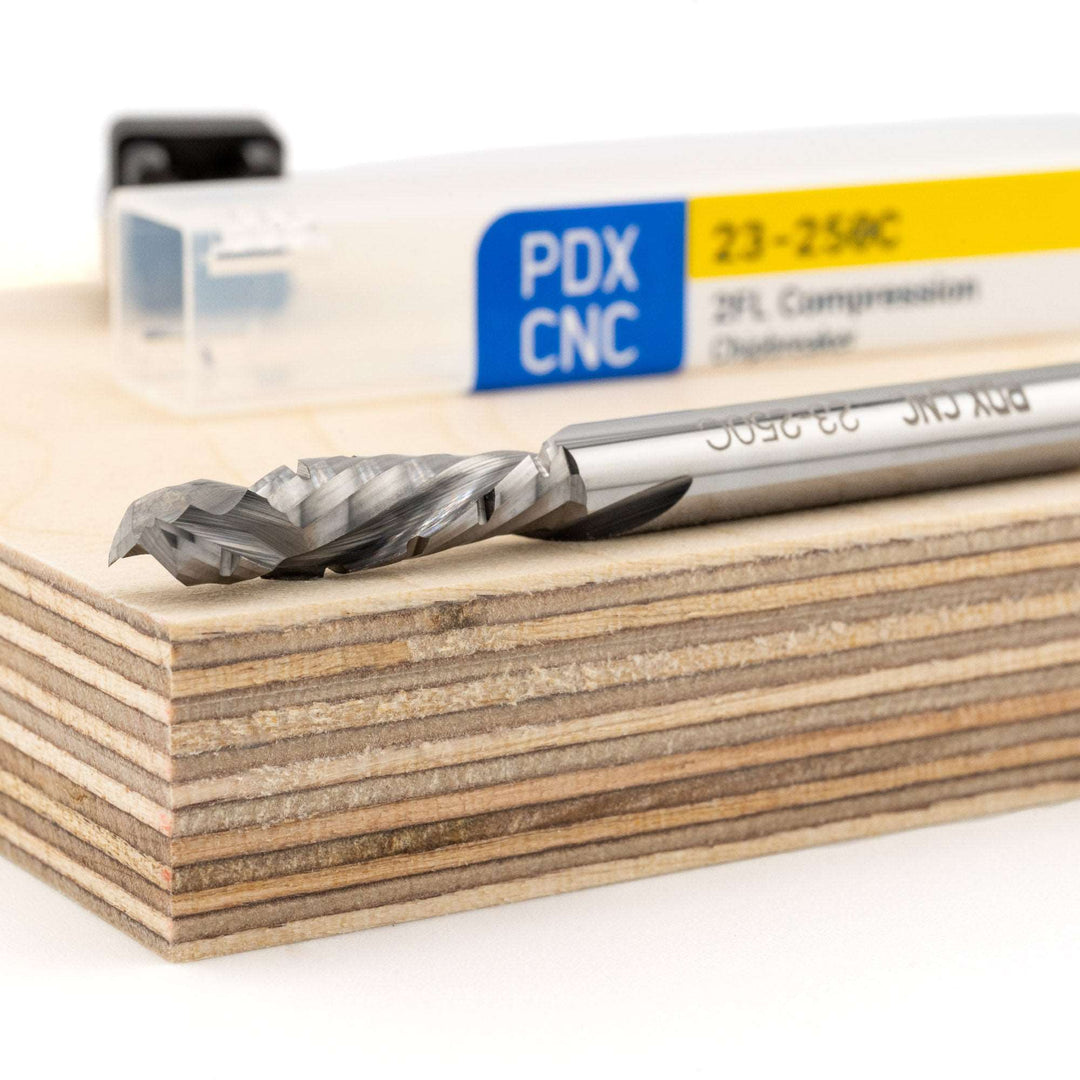

Our ShopSabre CNC Router needed an improvement in the dust collection department. After upgrading our ATC Pedestals we set out on designing an upgrade to the spindle Dust Boot.

After hundreds of hours and many iterations, we are happy to announce the PDX CNC Dust Boot.

GET OUR F1 / F4 MOTOR & BRUSH MAINTENANCE GUIDE

Leave a comment