ShopSabre CNC Router Tips and Hacks

We have a 2017 ShopSabre PRO 408. We’ve found a few ways to improve it over time. Here’s a few of those:

WARNING: AS WITH ANY CUSTOMIZATION TO ANY MACHINE, YOU ARE SOLELY LIABLE FOR ANY ISSUES, DAMAGE, OR WARRANTY VOIDING OF YOUR EQUIPMENT THAT MAY ARRISE FROM USING OUR SUGGESTIONS BELOW.

Auto Tool Height

Click to view our generator to create your ideal G-Code file. Run the file to automatically tool height the appropriate tools.

Spindle Warmup

Warmup Location

We adjusted where the spindle warms up so we can do some setup on the front of the machine and have the spindle be spinning safely away from the tool rack as well. The location on our 408 we like is X25Y60.

After warmup, Move to Back left

We found that the machine moving quickly to the front of the table (near the origin) felt dangerous as we are commonly setting up fixturing or a job. Instead, we have it go to the back left or X-4Y98 so it’s totally out of the way and not moving at where the operator is most likely to stand.

To do this you need to edit the WARMUP.MAC file in the WinCNC folder. Make sure to do this while you are not running a job.

You should compare our code below to your file and make sure to only replace the parts you understand.

Most likely you’ll need to restart WinCNC and re-home the machine before using this new code.

WARMUP.MAC

m11c9

G90

G53Z

G53X25Y60 [Moves to position for warmup]

s10000 [Spindle set to 10000]

M3 [Start Spindle]

G4X600 [Dwell for 600 seconds]

M5 [Stop Spindle]

G53X-4Y98 [Move to after warmup]

m12c9

Dwell - Make a note

Do you have important places in your operations where you need to watch for a tight tolerance or add more fixturing like screws?

You need to use a Dwell! The code, G4 will cause a ShopSabre to stop what its doing. WinCNC will show a dialogue to ask you to Push Enter to continue.

We used this for many things. Mostly for making sure the operator does something in the right order or as a reminder like, “DID YOU CHANGE THE ORIGIN FOR THIS OPERATION?”

You can hand-edit the code as needed in a text-editor but we use Fusion 360 with a pass-thru NC Program operation.

G0 Z10 [THIS MOVES UP IN Z TO 10]

G0 Y40 [MOVE MACHINE BACK TO Y40]

[ADD A NOTE TO THE OPERATOR]

G4

Modify Bed for Fixturing

We drilled and tapped our ShopSabre CNC Router frame to add more work holding options. Let's walk through how we did that.

Read the Article for drilling Feeds & SpeedsUpgrade to add more Tools

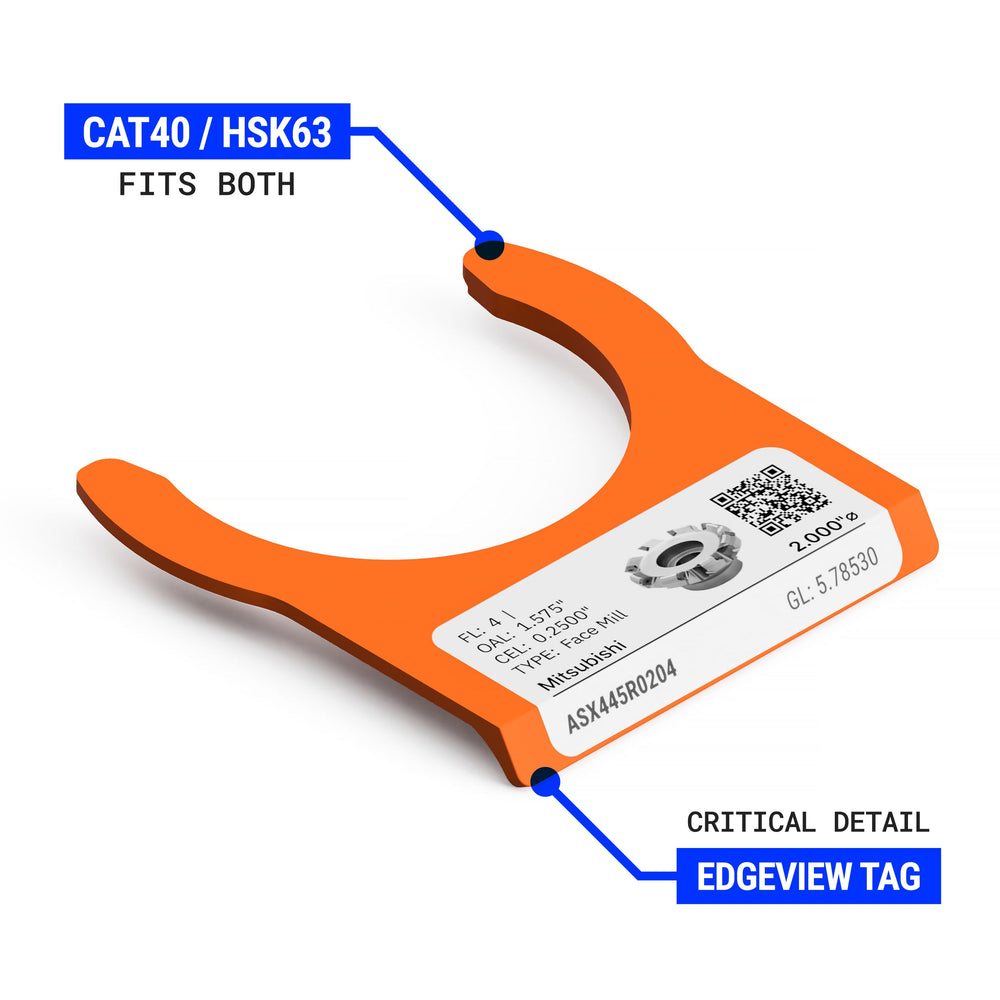

Use our Modular ATC Pedestals to upgrade your router.

ShopSabre PRO/IS Upgrade Options:

Numbers below allow for Z-Touch Probe Stand as well.

- ShopSabre PRO 404 & 408 (Bed X: 60") - up to 12 tools

- ShopSabre PRO 510 (Bed X: 72") - up to 14 tools

- ShopSabre IS 408 (Bed X: 65") - up to 13 tools

- ShopSabre IS 510 (Bed X: 75") - up to 15 tools

- ShopSabre IS 612 (Bed X: 85") - up to 17 tools

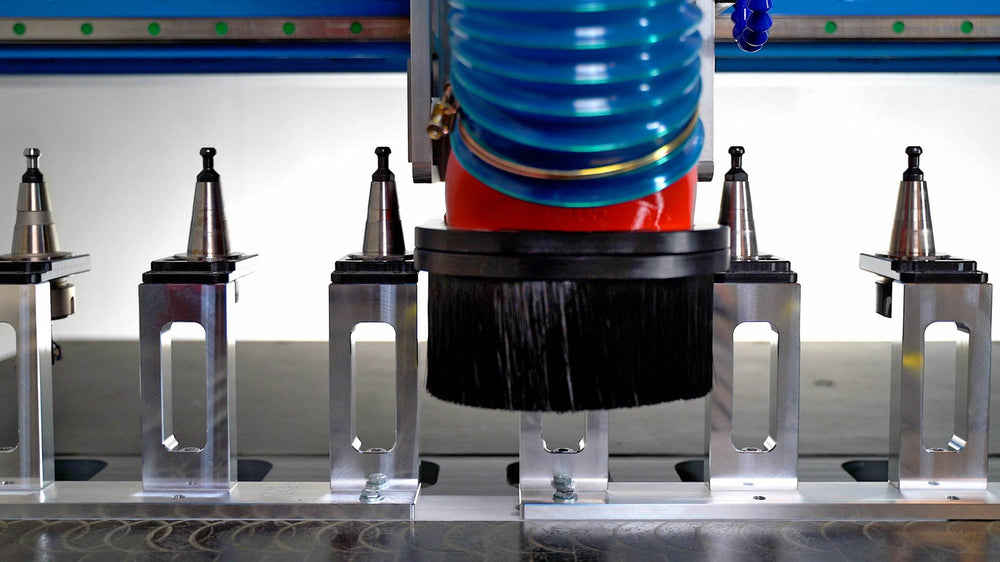

Upgrade your Dust Collection

Get our Dust Boot to upgrade your dust collection by 90%

DO US A FAVOR — SUBSCRIBE TO OUR YOUTUBE?

Click to subscribe ⤴

Leave a comment