Add Tools to your CNC Router

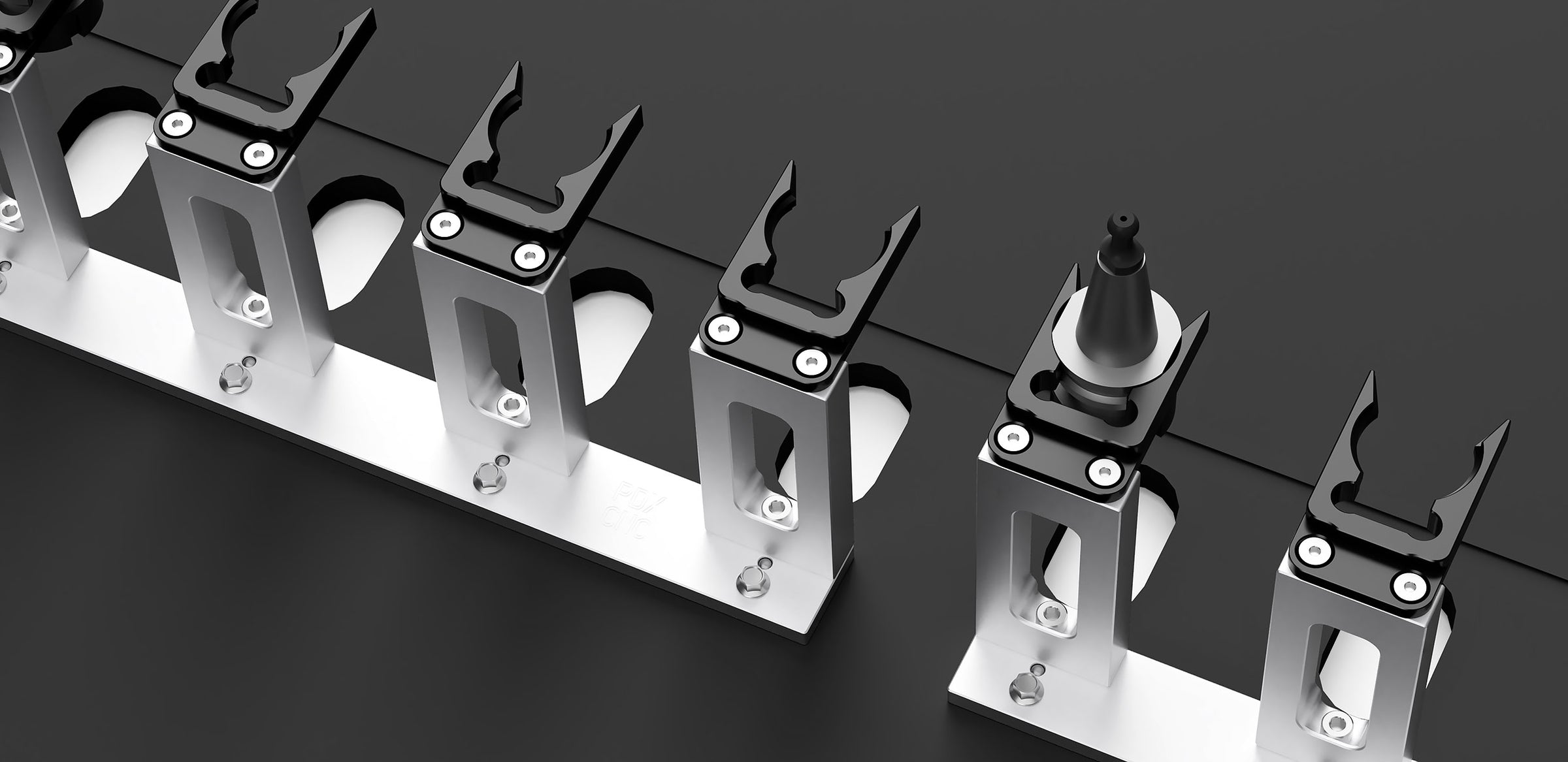

Need more tools for your CNC Router? Our ATC Pedestals are designed to be a minimal stand to hold ISO30 tool holders for an Automatic Tool Changing Spindle. We designed this first for our ShopSabre PRO 408 to upgrade to 12 tool positions.

Precision

There's a high level of accuracy, repeatability, and positive location built into the design of our Modular ATC Pedestals.

We use precision alignment dowel pins to align the Bases, Risers to the Bases, and indexed our forks with self centering mechanisms that won't slip around or change position after repeated used.

Our Pedestals are made on a CNC Mill accurate to thousandths of an inch.

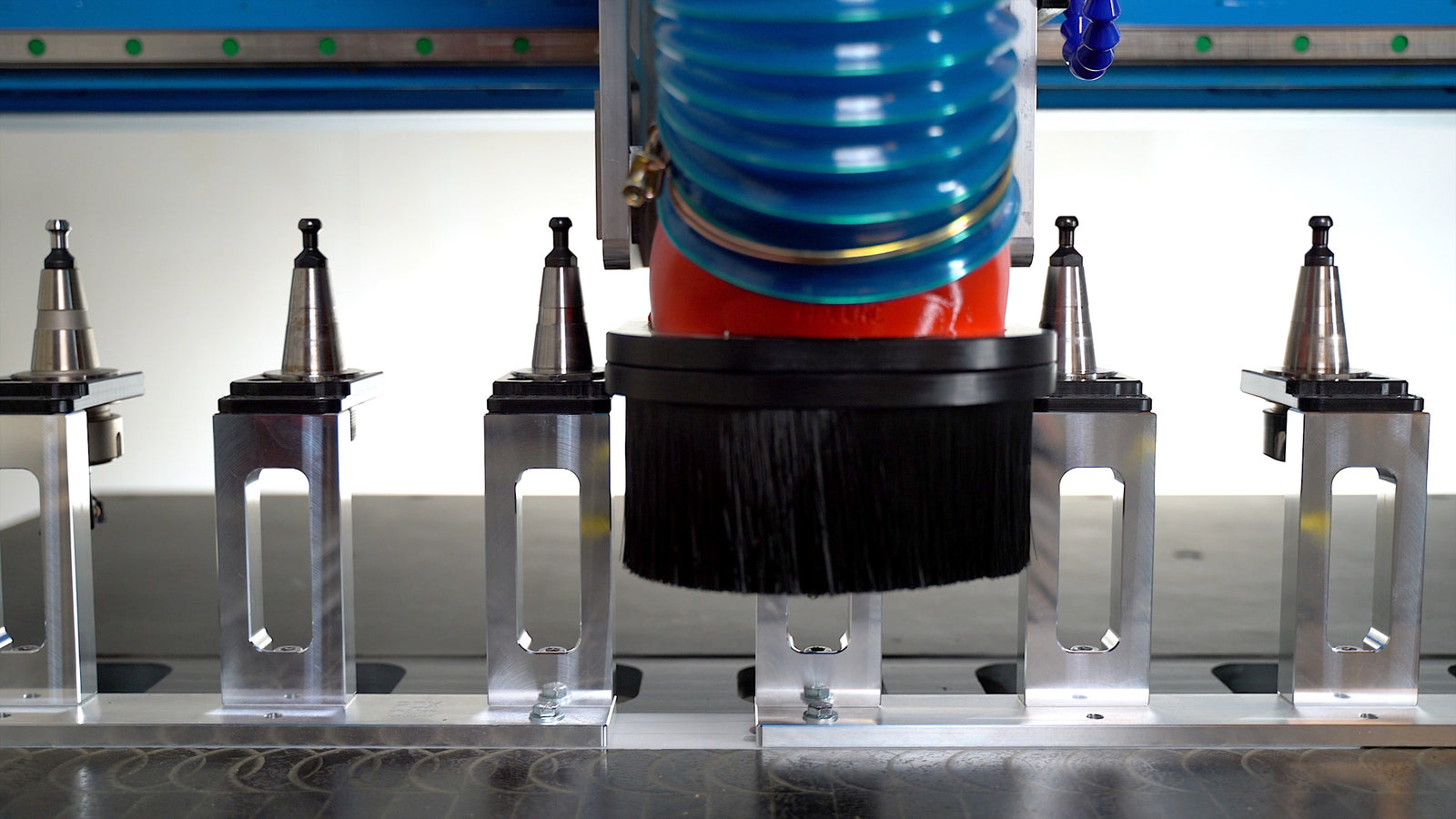

Dust Collection Improvements

No more smashing brushes on bar racks. When combined with our Dust Boot, you'll be able to run without docking and save valuable time while using our improved airflow and Dust Boot accessories.

Modularity = Flexibility

The parts of our ATC Pedestals are designed to be flexible. Flexible to work with just about any ISO30 tool changing CNC router. All the parts work together so if you start with a fast-swap Drop-in Kit you can re-use and add needed Risers and simply buy new Forks and Bases.

Upgradable

If you have the need or budget for smaller set of positions but later want to upgrade, simply add on to your system. We're happy to help you figure out the most cost effective way you can get what you want accomplished.

Replacements

If a part happens to get damaged or needs replaced, you only need to replace those parts, not the whole thing like most bent steel options.

Customization

Do you need a slightly different configuration? We can probably make that happen for you as we designed the entire system ourselves - it's all parametric Fusion 360 models. Get in touch for custom solutions.

Details

Our ATC Pedestals are Modular with three Mounting Base lengths (2, 3, 4) with our Standard Riser and ISO30 Fork to get just the number of tool positions you need.

ShopSabre PRO/IS Upgrade Options:Numbers below allow for Z-Touch Probe Stand as well.

- ShopSabre PRO 404 & 408 (Bed X: 60") - up to 12 tools

- ShopSabre PRO 510 (Bed X: 72") - up to 14 tools

- ShopSabre IS 408 (Bed X: 65") - up to 13 tools

- ShopSabre IS 510 (Bed X: 75") - up to 15 tools

- ShopSabre IS 612 (Bed X: 85") - up to 17 tools

Tool Capacities above for most standard spec'd machines after 2017.

We also offer New Z-Touch Probe Stands compatible with your ShopSabre probes.

Our ATC Pedestals are not exclusive to ShopSabre CNC Routers, however we have developed them using our 2017 PRO 408. They should work great on any ISO30 Auto-Tool-Changing CNC Router or robot 👀.

But wait, we can double that.

You can add quite a few more tools if you want to sacrifice about 12-14 inches of Y travel you can add an additional row(s) of tools in front of the normal row.

Without some extensive WinCNC reprogramming, 40 tools is the limit.

Please get in touch if this is something you are interested in!

Want better Dust Collection but not more tools?

See our Drop-in Kit - a no modifications needed option for ShopSabre CNC Routers.

FAQs

If you have a ShopSabre PRO or IS model, there are two main options: the Drop-in or the Modular ATC Pedestals, which can be configured with any number of tool positions from 2 to 17, depending on your machine. We have a full comparison here to help you choose, and we're always happy to help you decide – just send us a message.

ShopSabre PRO/IS Upgrade Options:Numbers below allow for Z-Touch Probe Stand as well.

Here's a list of things you'll likely need to do for most ShopSabre CNC Router tool upgrades:

Have the ShopSabre Drop-in Kit? See that guide here.

- Remove any existing racks and disconnect the tool height probe.

- Use one of our CAD pattern files to machine an extended slot and drill mounting holes into your CNC bed (Phenolic or MDF)

- Ideally, you'd drill and tap into the steel frame below your bed by hand. We don't recommend drilling or tapping with your router spindle.

- Alternative mounting could involve using washers and nuts or backup blocks below bed surface but we have not tested this.

- Phenolic is likely strong enough to be tapped itself. We recommend tapping into the steel frame, however.

-

Mount Bases onto Bed

-

Mount Risers on Bases

-

Mount Forks on Risers

-

Mount Tool Height Probe

-

Change WinCNC files:

-

For New Number of Tools

-

Set New Positions of Tools (XYZ Coordinates)

-

Set New Position for Tool Height Probe

-

We offer guides and as much assistance as we can. If you are savvy you can DIY with our guides and be running in hours. If you're local to Portland, please contact us for options!

Most likely - that's a big perk of our modular system is we've designed it to allow us to customize each aspect. Please contact us about customizations prior to any purchase.

See the rest of our FAQs here.