Cut More, Clean Less

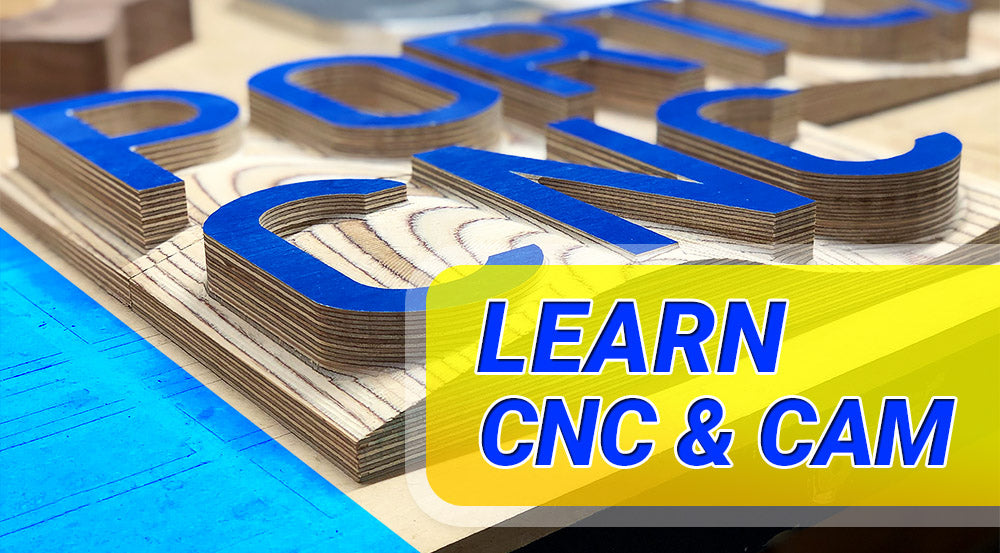

💨 BIG CFM BOOST

The Dust Boot has a standard 5-inch intake port. Theoretically, this allows 545 CFM which improves from the 3.4-inch internal port on the stock dust boot port (~288 CFM).

EASY NO-MODIFICATION SWAP

No need to modify your ShopSabre Router.* You can swap out your existing dust boot with ours in a couple of minutes.

Two-minutes and a Phillips Screwdriver

*If you have a center-mounted tool touch probe on the ShopSabre ATC Rack, it will need to be moved to the left side. Here's our guide. It’s easy, no sweat!

STOP DOCKING

Stop docking and use our Our Dust Boot with our ATC Pedestals to tool change or touch off tools. This means you save about 20 seconds per tool change over a docking system per tool change.

At 20 sheets a day with 3 tool changes each, you’d save 20 minutes per day in docking time alone. That’s 2-3 more sheets cut in that docking time! Thats 500-800 more sheets a year 🙊

Details

Not on our list? Signup to let us know you're interested.

What to Expect:

- Versatile Cut sheets or 3D machine with improved dust collection.

- Uses standard 5-inch flex duct - Available here

- Direct swap, no modifications*

- Works on many spindles:

- HSD ES915 5HP spindle - 100mm diameter nose

- HSD ES919 10HP spindle - 100mm diameter nose

- NEW – HSD 2.3HP spindle - 75mm diameter nose - on ShopSabre 23

- NEW – Hiteco 4HP spindle - 75mm diameter nose - sold with Avid machines

- NEW – Colombo spindle - 85mm diameter nose - sold with Multicam machines

- NEW – HSD 9HP AT/MT 1090-140 - 85mm diameter nose - sold with ShopSabre machines

- 89% CFM increase over stock ShopSabre 4-inch boot

- More Compact than original = more chip collection power

- Wood Dust is a Carcinogen - Capturing dust at the source makes for a safer work place.

- Stop Docking - 20 seconds faster per tool change. Save 20 minutes a day on Docking!

- ShopSabre Dust Dock movements should be disabled - (easy two-line WinCNC modification)

- Made by PDX CNC in Portland, Oregon

- Compatible with PDX CNC ATC Pedestal upgrades - improvements in dust collection and added tool capacity.

👉 Have a ShopSabre?

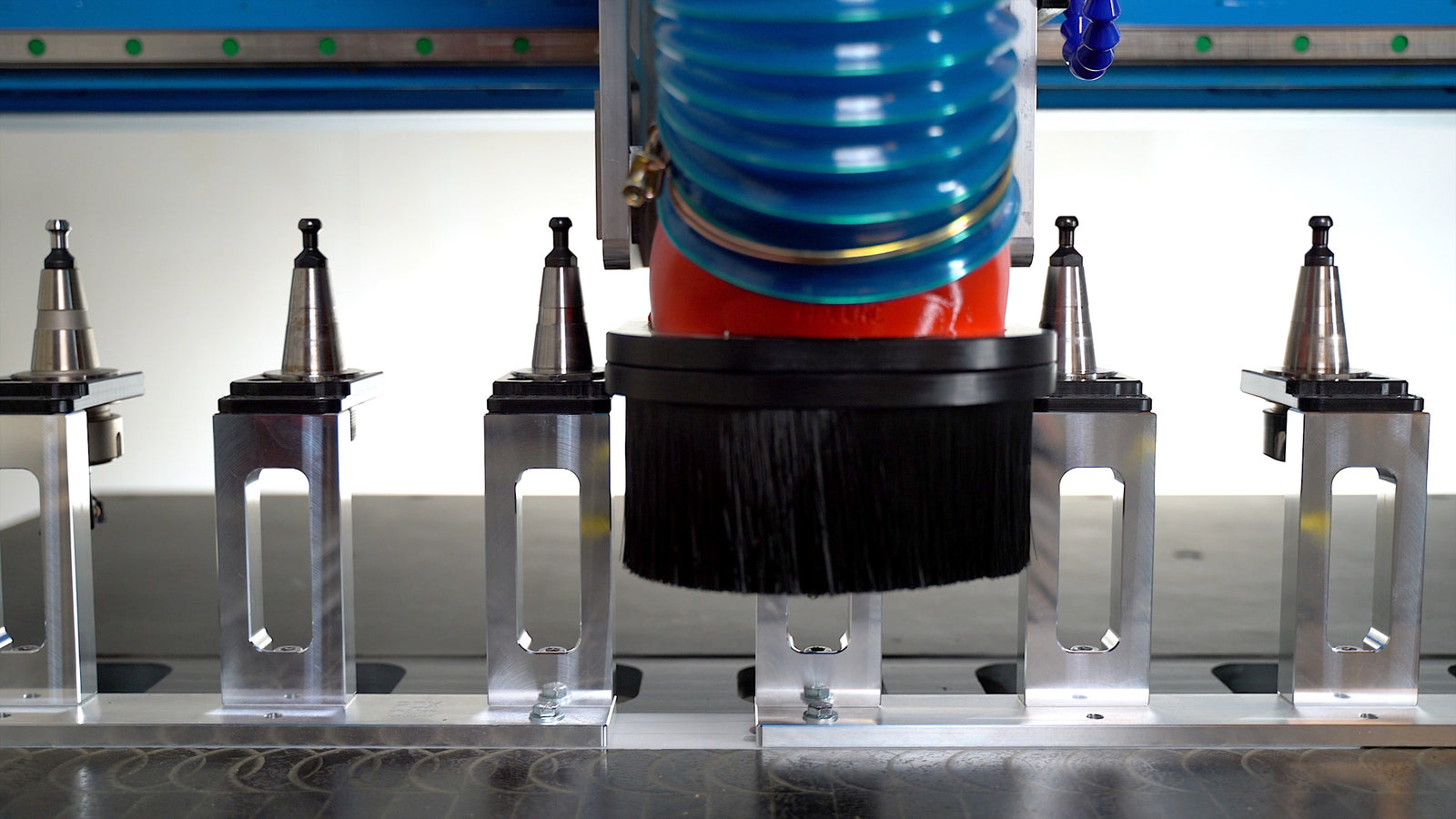

- NEW – Slim Brush Plate is compatible with ShopSabre ATC Pedestal-like rack.

- For the best quality and experience, we recommend using our ATC Pedestals.

- The older blue solid bar ShopSabre rack will deform the lower brush and cause shortened life.

How much will this help?

Your potential performance increase*

Data Source and factors that affect performance*

Options

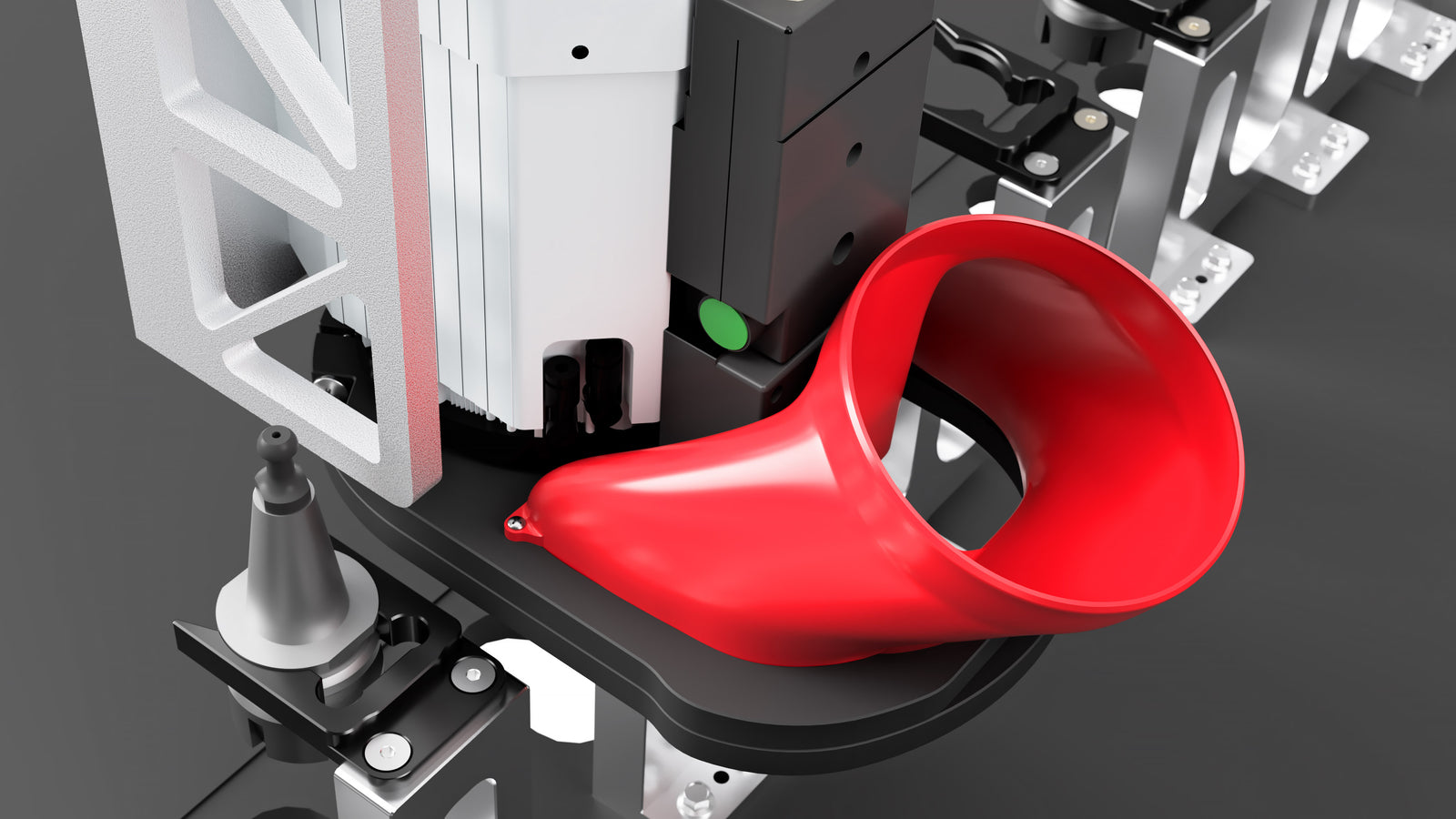

- Mounts

- 100mm - HSD Mount - 5-inch port

- 85mm - HSD Manual Tool Change & Colombo - 5-inch port

- 75mm - HSD and Hiteco Spindles - 5-inch port

- Lower Brush Plates - Lower swappable portion with brush in different lengths

- 3-inch length brush

- 3.4-inch custom length brush

- 3.4-inch New - Slim Brush Plate Or get multiple.

- 5-to-4 Reducer Kit - for those who max out at 4-inch ducting

This will have reduced performance as our Dust Boot is designed for a 5-inch duct.- 5" to 4" Duct Reducer Fitting

- 5" Duct Clamps (2)

- 5" Flex Duct connector piece * Estimated ~22% CFM improvement with 5-to-4" Kit versus the stock boot whereas 5-inch Port is an ~89% improvement.

- Now Available:Laguna SmartShop II and M, additional mounts

- Upcoming: Other Lower Brush options: Optimized for PDXCNC ATC Pedestals & other brush lengths.

Includes

- Dust Boot with 5-inch Port

- Magnetic Brush Plate

- Better Dust Collection 😉

FAQs

We recommend using our Dust Boot with our ATC Pedestals (on ShopSabre machines).

The Dust Dock movements should be disabled which is an easy two-line code modification in WinCNC.

We have a quick guide on how to do this.

WILL IT WORK WITH MY MACHINE? See the Compatibility List Our Dust Boot works with HSD spindles like those that ShopSabre machines uses. The mounting point of the Boot fits around the "spindle nose” just above the gage line. We know it works with:

- HSD ES915 5HP - 100mm

- HSD ES919 10HP - 100mm

- HSD 9HP AT/MT 1090-140 - 85mm

- Colombo - 85mm

- Hiteco 4HP - 75mm

- HSD 2.4HP - 75mm

If you have a stock ShopSabre PRO or IS machine with an HSD spindle, and the newer ATC-Pedestal-like rack you can use our NEW – Slim Brush Plate. The older solid bar blue rack we recommend using our ATC Pedestals. The solid bar ATC rack will deform the lower brush and cause shortened life.

It will not work with the ShopSabre Dust Dock – we recommend disabling that in WinCNC.

Multicam AU rotatary and most linear ATC rack with HSD spindles work fantastic with our Dust Boot.

There's also been AXYZ machines that use our Dust Boot as well.

Yes, of course. You’ll never clean out a compression cut fully - well maybe if you had the best dust collector ever made. With any Dust Boot, if the brush isn’t touching the work surface you’ll lose a drastic amount of suction and you’ll have chips spray out.

The key is to optimize your tool length (choke up) and Dust Boot capability like an optimal brush length for the job. We do plan to offer different options for spacers and brush lengths for our Dust Boot - this is not yet available.

We designed our Dust Boot to provide the most airflow CFM as close to the spindle while having as long a brush that makes sense. It’s not perfect, but it’s an improvement.

Yes! You can try your machine out if you think it might fit with no risks:

Try our Test-Fit Guarantee.

We are always interested to hear what machines we should support next. Let us know what machines we should support.

Can't find your question? See all of our FAQ's

You may also like

Brand new

Fresh

Be one of the first to get our newest products and enjoy launch pricing – while it lasts.